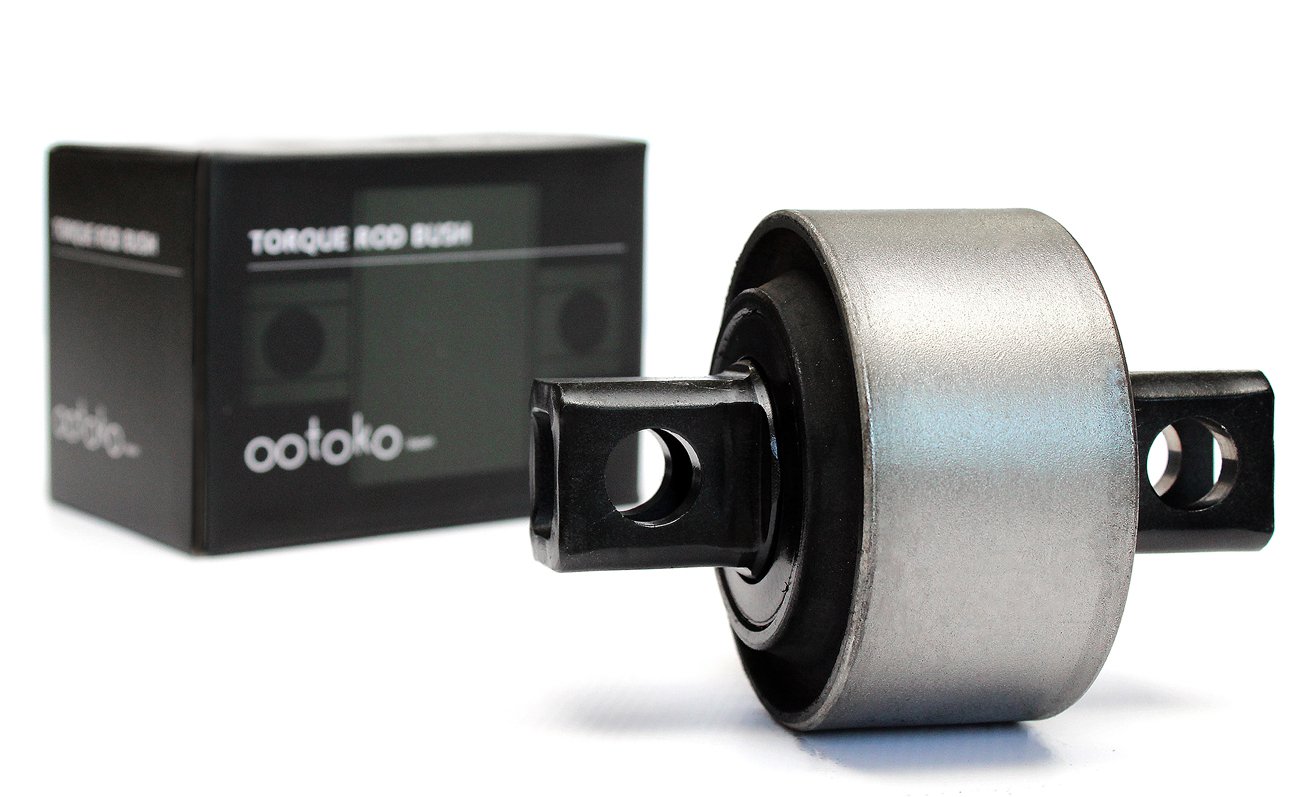

OOtOkO brand was founded in 2006 in Japan.

-

The main business of the company is the production of spare parts for light and heavy trucks. The distinctive features of these products are their high quality and reasonable price.

This combination was made possible by the decision of the company's management to produce all parts outside of Japan, but using Japanese technologies, compliant with thus standards of raw materials and key components made in Japan. And at the same time to carry out a strict control at all stages of production.

Today the OOtOkO factories are located in several Asian countries, but at the same time all assortment of spare parts of the brand is of high quality.

An indication of the quality of OOtOkO products is that the company factories are suppliers of parts to the automotive conveyors Hino, Mitsubishi, Isuzu, Toyota, Nissan.

All items are made from the best materials with the use of modern production technologies.

-

The company employs a team of technical experts from Japan, which has extensive experience in the sphere of production of spare parts. They inspect the factories and control all production stages of parts and also on-time delivery of components to the assembling lines.

Goods made in Japan, always value for unsurpassed quality.

Production quality at every factory of the company is certified. We have certified testing laboratories.

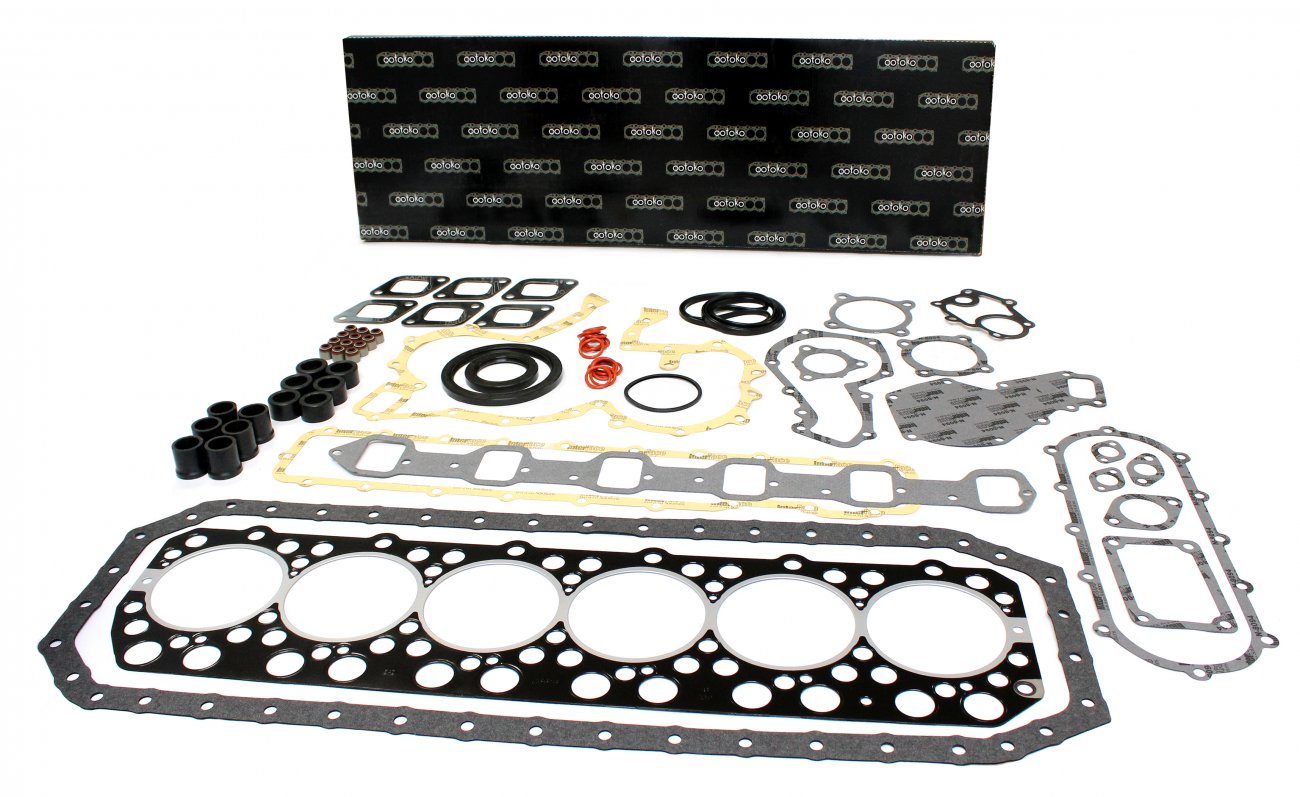

Technical testing of finished products are carried out according to the company regulations:

-

selectively tested a certain % of the batch (suspention parts);

-

testing of the first and last of every batch (such as lamps and rubber parts);

-

100% all of the party (parts with electrical components).

-

Launched production of brake system parts.

- brake linings for drum brakes

- brake pads

- brake disks

- brake hoses

The entire range of brake linings and brake pads are produced asbestos free, which meets all European quality standards.

Under the requirements of clients from different countries, two types of rivets are included in the pad kit - aluminum and brass.

The boxes are made from a durable multilayer cardboard, that can avoid losses of marketable product condition of packaging after multiple transportation.

Brake disks are produced by TOYOTA standards.

EAC Certification.

OOtOkO has applied for certification of products to comply with the standards of the Customs Union (EAC).

Now our customers from countries inside the Customs Union (Armenia, Belarus, Kazakhstan, Kyrgyzstan, Russia) will be able to freely import the goods produced by OOtOkO.

New products in development.

Currently, OOtOkO company is developing and manufacturing auto lamps for Japanese trucks.

The challenge is to make tail lamps, front and corner lamps with quality as close as possible to Japanese Koito and Stanley, which are suppliers to automotive assembly lines and considered to be original (OEM).

It is expected that these products will occupy a niche between cheap Chinese products and original. Quality will stand in a row with products of DEPO and TYC from Taiwan, but with a more attractive price.

We have already completed production of most moulds for casting housings and lenses and all samples are testing in laboratories now.

By June 2016, we will be 80% ready of the expected range, and will be shipping to distributors.

Feedback

Do you like these products and would you like to buy it?

Do you have questions or suggestions regarding OOtOkO spare parts?

Leave your contact details and our representative will contact you shortly.